Our company was established in 2006 as a small manufacturer of equipment, specializing in semiconductor lithography mask alignment of development and manufacturing of the exposure and the exposure source, the light box from the optical exposure within the design to complete various types of exposure the company after years of efforts have been developed entirely completed and shipped many customers at home and abroad, deep acclaim.

-

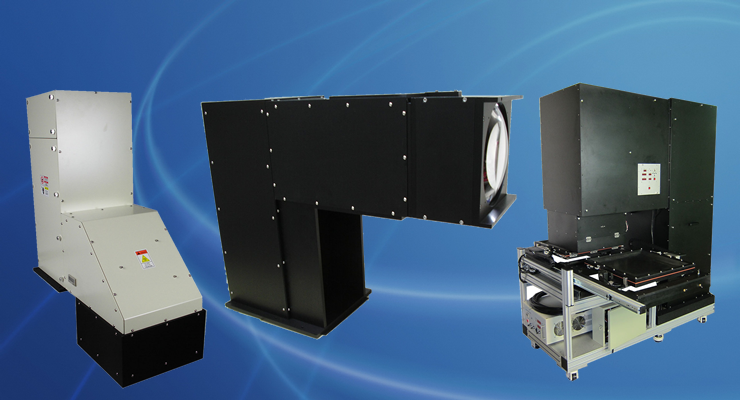

Mask aligner

High yield automatic exposure machine, alignment process can produce 250 or more per hour, no registration process can produce 350 or more per hour, the wafer transfer automatic machines for the automatic input and output, the output of the industry’s highest , twice the other brands models.

-

Exposure source

Optional light intensity flyback type power supply to the light intensity inside the box detectors do feedback control signal, the light intensity output enables long-time stable, uniform beam generated by the array of lenses, making pattern transfer can effectively reduce the exposure light diffraction.

-

Mercury lamp power supply

Digital display panel output power and voltage and current values, internal electromagnetic contactor do overload protection, rear connectors output power box fan, light boxes and overtemperature protection interlock circuit, good operating performance, good stability, high durability, the most suitable production line.

-

Components

There is no content, do not know what to write, you just write it to occupy layout. But in many ways, when we catch the Bund sidewalk, formal dance, eventually everybody will applaud, I built this company, Cool !!

2012.10.18

Check vacuum diaphragm for cracks and need to be replaced, if the vacuum diaphragm is also well placed properly, can then try to adjust the vacuum adsorption, if the situation did not improve, it may be blocking the pipeline, to be demolished pipeline cleaning.

Adjust the magnification of the image so that align key accounting screen 1/4 to 1/2 size to readily find align key premise of maximizing the rate to increase resolution.

We generally use American ARC mercury lamps For use Ushio, Osram mercury lamp and other brands, we can also fit design.

Our double-sided exposure machine is aligned with the alignment back lens groups can be used for the back of the place.

Yet before lighting voltage display should have more than 100V voltage value, if there is no voltage, temperature protection switch may be behind the line not connected, or the power supply itself is faulty.

2KW high pressure mercury lamp is a co-xenon lamp, 2 to 3 million volts of high pressure lamps, high-voltage power supply of this process will produce a loud sound of electric shock is normal.